- 01302 492 050 (Office) / 07949 737 872 (Mob)

- sales@dutchcon-eng.co.uk

Our Projects

Find out more information about our completed projects for our happy clients

General Fabrication & Repairs

- All

- Steel Bracketry

- Steel Frames

- Mesh Frames

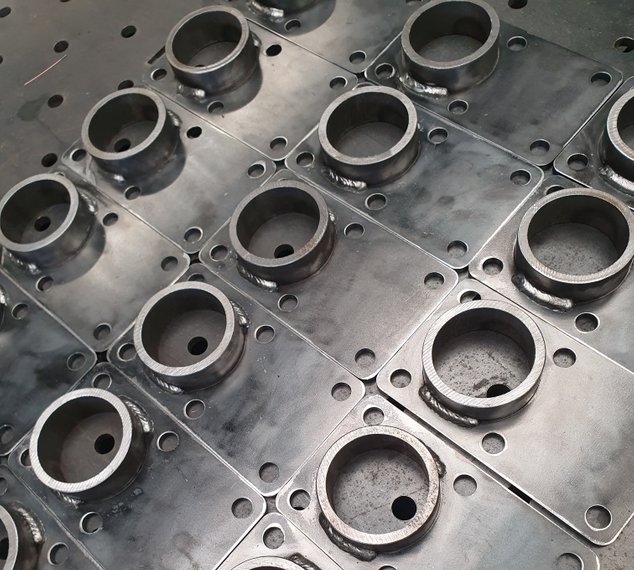

- Custom Made Fittings

- Locomotive Repairs

- Rail Freight Wagons

- Steel Casings

- Augers

- Filter Cells

- Steel Ducting

- Square to Rounds

- Flood Barriers

- Site Work - Mechanical Repairs & Fitting

- Stainless Steel Bracketry

- Steel Barriers

- Steel Chutes

- Bottle Banks

- Site Welding

- Full Turnkey Projects - Assemblies

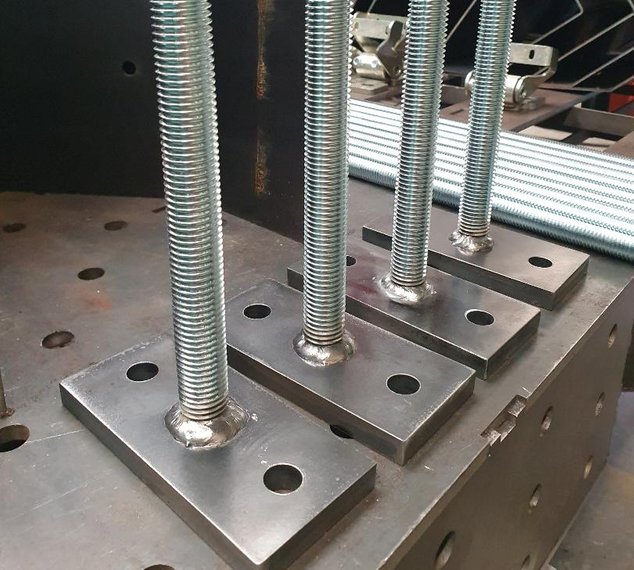

- Jig Work

- Structural Components

Project Case Studies

Air Slide & Fabric Filter unit repairs for the quarry industry

Dutchcon services were required to repair an Air Slide and Fabric Filter unit due to blockages and insufficient flow of cement material. Our experienced team worked meticulously during the shutdown period to meet all client requirements and ensured the optimal function of the system.

Our priority during this task was not only to deliver quality workmanship but also to maintain the highest level of safety. To achieve this, we carried out extensive Risk Assessment Method Statements (RAMS) before commencing any work on-site. In doing so, we made certain to identify potential hazards and put in place effective control measures for each process involved in the repair works.

The detailed planning along with our engineers’ exemplary skills allowed us to handle various challenges effectively and finish the tasks within schedule. We trust that our diligence met our clients’ expectations making way for a continued partnership with them.

The team demonstrated exceptional workmanship throughout the project, displaying a level of skill and expertise that is not only commendable but also reflective of our commitment towards delivering top-tier solutions for every task we undertake.

- Project Management

- Planning

- Risk Assessments / Method Statements (RAMS)

- Site Services

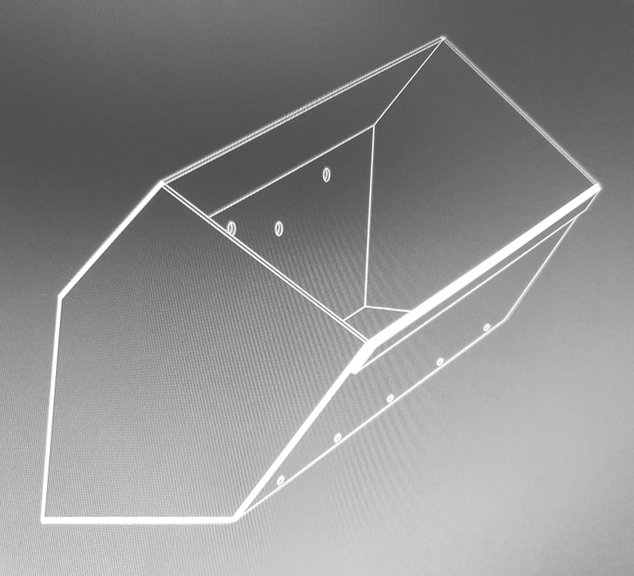

Flood Barriers

Dutchcon Engineering were approached by a home owner as they recently were affected by the unfortunate event of flooding and were seeking a sustainable solution to protect their home. We offered our expert services in custom-fabricated aluminium flood barriers which met their needs.

The aluminium flood barriers showed resilience, durability and strength while being lightweight and easy-to-install at the same time. Moreover, they require significantly lower maintenance due to their corrosion-resistant properties.

What set us apart from other providers is not only our high-quality products but also our commitment towards ensuring customer satisfaction. As part of our package, we provide an initial assessment completely free-of-charge. Furthermore, should you decide to proceed with us, we will arrange for seamless fabrication followed by professional installation of these barriers at your preferred schedule.

- Initial Site Visit

- Free Estimate

- Procurement

- Manufacture

- Packing & Delivery

- Final Installation

Nose ring fan outlet pipe fabrications for the quarrying industry

Dutchcon Engineering were approached by a Quarry Site to produce a Nose Ring Fan Outlet assembly for their shutdown project. All engineering drawings were free issued by the client for our review, subsequently pattern development assessments were carried out by Dutchcon to ensure true geometry and ease of fit up on site.

The fabrications included products such as Lobster Backs, Square to Rounds and Support Saddle Structures.

All fabrications were requested in a short timescale to which the delivery deadline was achieved.

- Project Management

- Planning

- Pattern Development

- Procurement

- Manufacture

- Packing & Delivery

- Final Document Pack

Steel elevator buckets for the quarrying / cement industry

Full turnkey project involving material supply, management activities, manufacture, packing and delivery.

- Project Management

- Planning

- Inital Dimensional Survey

- Engineering Drawings

- Procurement

- Manufacture

- Packing & Delivery

- Final Document Pack

Class 20 diesel locomotive - filter housing frames and battery box repairs

Our experienced team worked tirelessly, ensuring a fast yet effective repair process was carried out efficiently. We adhered to strict safety standards, guaranteeing high-value services at all times whilst maintaining a quality repair.

Our team demonstrated exceptional workmanship throughout the project, displaying a level of skill and expertise that is not only commendable but also reflective of our commitment towards delivering top-tier solutions for every task we undertake.

In line with this achievement, we are enthusiastic about offering similar services on a larger scale as part of our continued aims for growth whilst upholding quality standards.

Similar project? If you wish to discuss potential collaborations involving such projects or other related inquiries, please feel free to reach out directly via email or call us at your earliest convenience.

- Initial Site Survey

- Risk Assessments / Method Statements (RAMS)

- Procurement

- Pre-Fabrications

- On-Site Fabrications

- Final Installation of components

Class 31 diesel locomotive - 2 off engine filter housing repairs

Dutchcon Engineering undertook a complex repair project on a set of Diesel Locomotive Mild Steel Filter Housing Frames, bringing them back to their original state.

Initial dimensional checks were carried out as no original engineering drawings were available for review. This was a complex project in terms of gaining accurate positioning and dimensions due to the nature of the deteriorated frames.

Once Dimensional Checks were completed we generated a set of engineering drawings to ensure pre and final fabrications were achieved to the original locomotive design specification. A second site visit was then included to ensure true fit prior to us procuring materials and arranging sub-contract work where necessary.

- Initial Site Survey

- Engineering Drawings

- Procurement

- Pre-Fabrications

- On-Site Fabrications

- Final Installation of components

- sales@dutchcon-eng.co.uk

- 01302 492 050 (Office) / 07949 737 872 (Mob)

- Company No. 12465429